The quality and food safety of our products is our main objective. We therefore select the raw materials and suppliers that can guarantee the specifications and technical and qualitative requirements of our customers.

Our production is carried out using whole fruits in order to guarantee their purity. We have our own grinding systems, as well as all the necessary mixing and packaging equipment.

As proof of our commitment to quality, food safety and the environment, we are IFS Food, ISO 9001:2008 and ISO 14001:2004 certified.

History

After having established the business, and with the old facilities becoming too small, an addition was built; the “new” factory, also in Cabezo de Torres (Murcia), with greater production capacity. A greater number of mills of the well-known Alcantud paprika grinding system and an improved product packaging system were installed.

Factories in La Matanza de Orihuela, Lobón in Badajoz and Cabezo de Torres in Murcia.

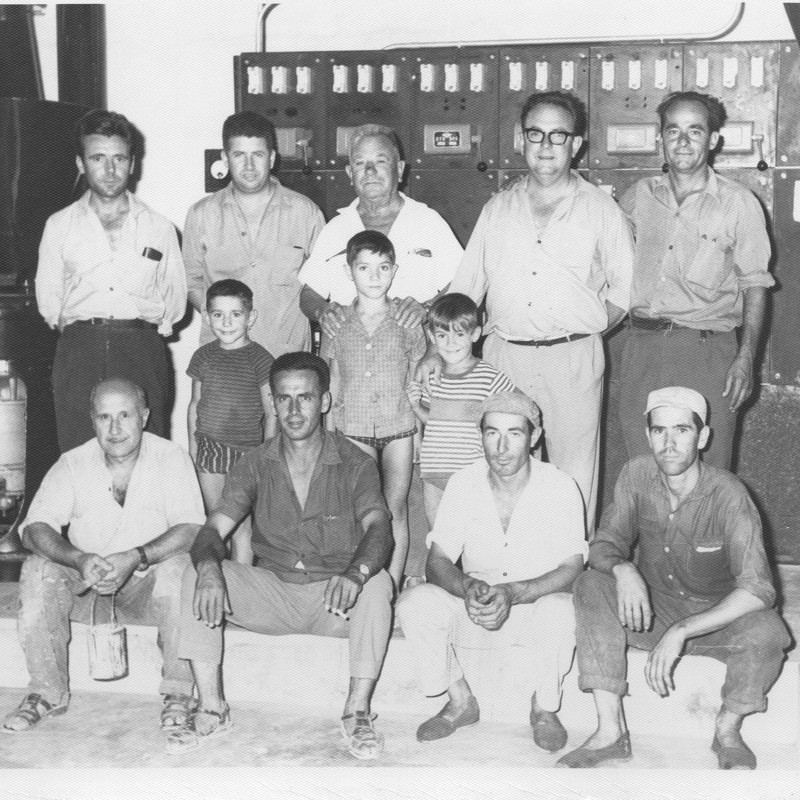

Three generations producing spices: José Sánchez Aranda and the brothers Domingo and Antonio together with the founder’s grandchildren.

With the expansion of our company into international markets, greater control of production became necessary and the incorporation of forced air dryers was introduced.

In these dryers, located in La Matanza de Orihuela (Alicante) and in Lobón (Extremadura), water cleaning was carried out prior to drying, guaranteeing the quality and safety of the product.

After the departure of three of the brothers, at different times in its history, two of them, Francisco and Antonio, eventually remained at the head of the company, running the business at the Cabezo de Torres facilities until the year 2000, when the current facilities of José Sánchez Aranda in Abanilla were inaugurated. Here the company has the most modern grinding, mixing and packaging systems.

The company is currently run by the third generation; the sons of two of the Sánchez García brothers.

Plantation

Our commitment to quality and safety led us to embark on an ambitious project for the production of paprika peppers. On our plantation we have more than 500 hectares of farmland for the production of peppers. We control everything from the seed, avoiding GMOs, to the arrival at our facilities in Spain.

We control the traceability of each of the plots in production, guaranteeing the application of the appropriate phytosanitary products, respecting the safety periods for the application and avoiding cross-contamination.

The peppers are dried in biomass dryers. This way we can guarantee the quality and food safety of our peppers and at the same time avoid atmospheric pollution by using renewable resources in the drying process.